METH2GEN

The European Research Fund for Coal and Steel has approved the project ‘Conversion of methane into hydrogen for energy generation and reduction of methane emissions’ acronym: METH2GEN submitted by a consortium of companies: INiG-PIB, JSW. S.A., GIG, PIG-PIB, AGH, UNIOVI (Universidad de Oviedo), INSEMEX (Institutul National de Cercetare Dezvolare Pentru Securitate Minierasi Protectie Antiexploziva Insemex Petrosani). The budget for the entire project is €25,673,524, of which JSW S.A.'s budget for project implementation is €20,429,561.

The METH2GEN project addresses the issue of limiting the methane hazard in mined hard coal seams and the economic use of methane from excess gas, which is currently released from the methane drainage station into the atmosphere. The final result of the project will be the implementation of an alternative and highly effective method of rock mass methane drainage with the use of directional drilling and the commissioning of an installation enabling the production of hydrogen fuel.

The Environmental Strategy, which is part of JSW S.A.'s Business Strategy, sets high requirements in terms of reducing methane emissions from JSW's mines. This necessitates the implementation of new, more effective methane drainage techniques. These include long-hole directional drilling technology. At present, the application of this technology in JSW's mines is hampered by the low supply of services and their enormous cost. On the other hand, the use of excess methane from methane drainage stations for hydrogen production will be a breakthrough in techniques for the economic use of methane captured by the methane drainage system. It will allow for 100% utilisation of methane captured at the methane drainage stations, which is of great importance in the context of the EP and Council (EU) methane regulation.

Methane accounts for approximately 73% of the carbon footprint of Jastrzębska Spółka Węglowa. To date, measures have been taken to increase the efficiency of mine methane drainage, including through the expansion of the methane drainage pipeline network, sealing of isolation dams and drilling boreholes into post-mining goafs, which will enable increased methane capture from these areas. The next step is to increase the efficiency of methane drainage of mine by increasing the efficiency of longwall methane drainage, using directional drilling. The introduction of LRDD (long reach directional drilling) will enable longwall methane drainage efficiencies of around 70% to be achieved.

Methane drainage using directional drilling is an opportunity for the Company to implement modern technology, reduce costs and develop employees. Until now, the use of this method for methane drainage was limited due to the small number of companies providing such services and, consequently, their low quality and high prices. Gradually building our own competence in this area will, in the long term, allow us to improve safety, reduce methane emissions into the atmosphere and limit future expenditures on methane drainage at all JSW plants. Increasing the efficiency of methane drainage means lower methane emissions together with ventilation air, and thus a reduction in methane emissions into the atmosphere.

The METH2GEN project, which on the one hand increases the level of methane drainage of mine workings and on the other allows for the production of hydrogen from waste methane, is an important solution in an era of the need to decarbonise the economy. In addition to the obvious environmental effect of reducing emissions of methane, which is a greenhouse gas many times more potent than CO2, hydrogen will be produced, for which market demand is growing. The production of hydrogen with the SMR system is economically justified and the projected high demand due to other developing decarbonisation technologies in Poland, Europe and the world is an optimistic forecast for the further development of the project.

SMR (Steam Methane Reforming) - Steam methane reforming (SMR) is the most common and cheapest method of producing hydrogen, but is not environmentally friendly on its own as it also generates CO₂. However, when combined with carbon capture and storage (CCS) or carbon capture, utilisation and storage (CCUS), it becomes an attractive method of producing blue hydrogen. Its main advantage is its full technological maturity, proven by more than 80 years of commercial use.

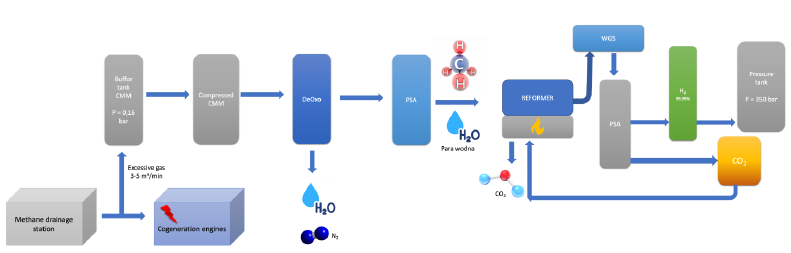

Preliminary concept of the hydrogen production process:

a. Accumulation of excess methane from the methane drainage station in a buffer tank,

b. Compression of the gas,

c. De-Oxo pre-processing - oxygen removal,

d. Pressure swing adsorption (PSA),

e. Steam methane reforming (SMR),

f. Carbon monoxide steam conversion (WGS),

g. Pressure swing adsorption (PSA) separation of hydrogen and carbon dioxide,

h. Condensation of CO₂

i. Compression and storage of hydrogen and liquid CO₂.